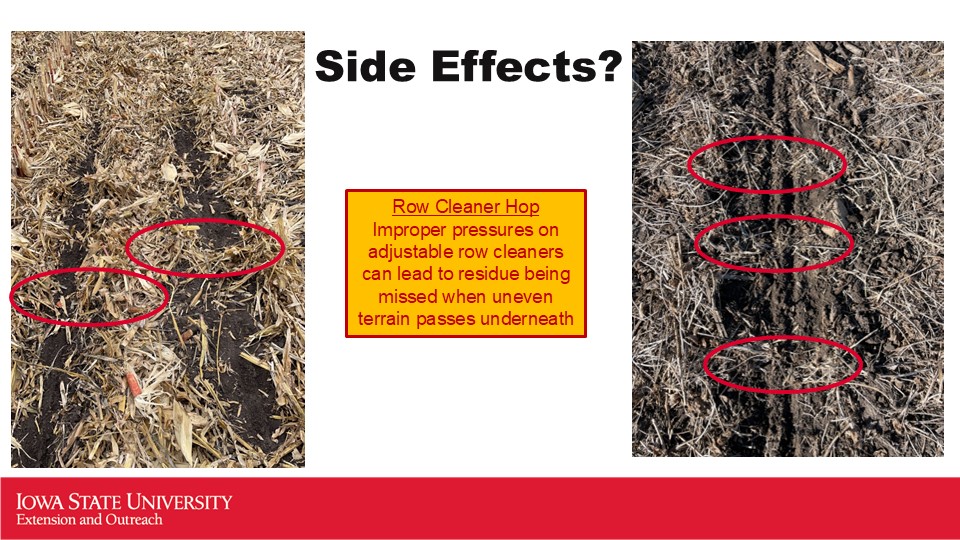

If your row cleaners seem like they won’t go low enough ensure that the row cleaners are unpinned and mounted on the correct holes. See the two images below that show two commonly used row cleaners that have adjustments and pins that can be moved.

The goal for row cleaners is to move as minimal soil while keeping a fixed engagement with the soil. In the images below we see that the stability of the row cleaners were too low. A solution is to raise the pressures in the up and down air bags.

Once in the field it is always a good idea to verify your Scribe Test was done correctly and closing wheels are aligned. In the left image below we see a furrow being closed by an unaligned closing system. This will cause air pockets which will affect germination and seed growth. The right image shows a closing system after being aligned in the field.

Skips-

1- Start with increasing your vacuum levels.

2- If the issue is not resolved start adjusting your double eliminator if your meter is equipped with an adjustable eliminator.

3- Remove the meter causing issues and inspect for logged broken seed or debris.

Doubles-

1- Start by lowering your vacuum setting.

2- If you start to see skip raise your vacuum back up and adjust your double eliminator more aggressively if equipped.

Skips- 1- Start with adjusting your double eliminator less aggressively. 2- Remove meter from machine and inspect for logged seed or debris Doubles- 1- Raise the aggressiveness of your double eliminator. 2- Inspect meter for worn out part allowing for multiple seeds to be grabbed.